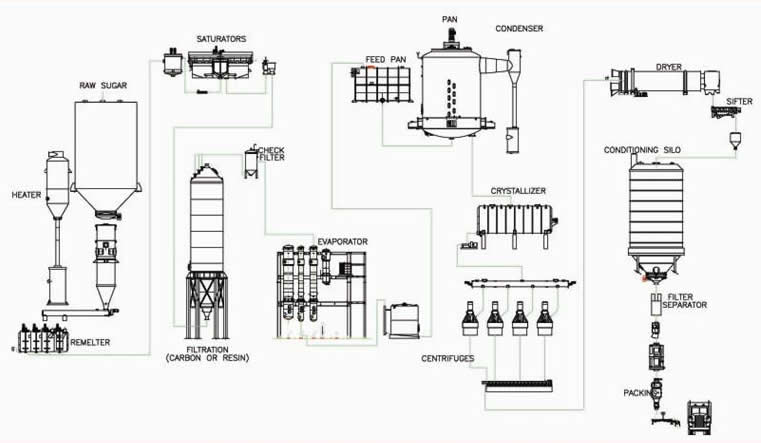

Process

Refined Sugar Production:

Sugar is refined either at the same location where it was produced as part of an integrated facility or at separate raw sugar refineries.

Basically the Refiners can have access to several Sugar qualities, as:

1.1- VHP

1.2- VLC

1.3- VVLC

1.1- VHP – Very High Pol Sugar.

This is the basic sugar today exported by most of the countries, especially Brazil. Most of the moderns Refineries work with this material.

The basic specifications are –

VHP specifications

| Color | > 800 | Icumsa |

| Pol | > = 99.3 | % |

| Turbidity | < 20 | NTU |

| Ash | > 1.000 | Ppm |

| Reducing Sugar | > 800 | Ppm |

The principle of a Refinery dimension is its capacity to remove some impurities as:

Color

Turbidity

Ash

So the high is each one of these values the bigger must be the Refinery installation and equipments, and the chemical consumption to handle the impurities.

More impurities means more sugar loss as Final Molasses and as removed as Scum, Mud, Ash and Undetermined Loss (UL).

As the Refinery has a limited capacity to remove all those impurities the higher the quantity of them the less will be the capacity and this will reflect on costs and quality.

The other important item that limits the production and productivity is the process Water.

So our recommendation is to look for sugar with a good quality, as Raw Material.

1.2- VLC – Very Low Color Sugar.

Is a sugar with a higher quality than the VHP.

All Brazilian Refineries uses this sugar, in order to work with a very small and simple Plant, with low steam, energy and chemicals consumption, and high productivity.

VLC specifications

| Color | < 500 | Icumsa |

| Pol | 99.5 | % |

| Turbidity | < 20 | NTU |

| Ash | < 800 | Ppm |

| Reducing Sugar | < 600 | Ppm |

1.3- VVLC – Very Very Low Color Sugar.

It is a special sugar produced to be direct used by some Industries.

The color is quite low and the quality is too high to be imported to refine.

VLC specifications

| Color | < 300 | Icumsa |

| Pol | 99.7 | % |

| Turbidity | < 20 | NTU |

| Ash | < 500 | Ppm |

| Reducing Sugar | < 400 | Ppm |

In the case that the VLC shall be used one can expect an increase in capacity and productivity, with lower operational cost.

Even with a sugar quality worst that the VHP, when and if will be the case, the Refinery can work and produce the same quality, obviously with a higher operational cost, due to the use of more chemicals, energy and steam.

PRODUCTS

The Project will be executed to attend the production of the Granulated Refined Sugar based on the ECC specifications, for the EC-2 type.

Meanwhile the Refinery can produce several others sugar type, on Clients request.

With the Liquor produced with our complete and highly efficient process, it is possible to produces basically all kind of sugar needed by the Market, with the Equipments installed.

The products can be:

- Refined Granulated Sugar EC-2

- Refined Granulated Sugar standard Bottlers producers

- Special White Sugar with different colors

- Icing Sugar

- Liquid Sugar (with some additional equipment)

- Invert Liquid Sugar (with some additional equipment)

For the Refined Granulated Sugar, EC-2, the specs will be-

Refined Granulated Sugar spec.

| Color | < 40 | Icumsa |

| Pol | > 99.90 | % |

| Humidity | < 0.030 | % |

| Turbidity | < 4 | NTU |

| Ash | < 300 | Ppm |

| Reducing Sugar | < 300 | Ppm |

| AM | 0.60 @ 0.70 | mm |

| CV | < 30 | % |